SERIAL PRODUCTION

The fast track to success:

Reliable high-tech serial production.

The best preconditions for a successful cooperation. The Pöppelmann KAPSTO® production is characterised by continuous quality, highcapacity production and exemplary cleanliness, including our proven quality management certified according to DIN EN ISO 9001:2008. Our environmental management system is inspected in accordance with EMAS ll and DIN EN ISO 14001:2005.

Systems with special requirements:

Highest technical cleanliness.

At Pöppelmann KAPSTO®, protective closures for applications with higher cleanliness requirements, such as fuel injection systems and vehicle safety systems, where even the smallest particle contamination can lead to failures, are manufactured by specially trained personnel in a specifically equipped cleanroom.

The advantages of serial production at a glance:

TECHNOLOGIES

More cost-effective for you: Using the right technology ensures success.

Whether weight reduction or particle-free seams: every day Pöppelmann KAPSTO® applies the latest technologies, such as the MuCell® method or hot-gas welding, for the development and production of plastic protective elements.

2C injection molding process

For sophisticated multifunctional parts with different plastics.

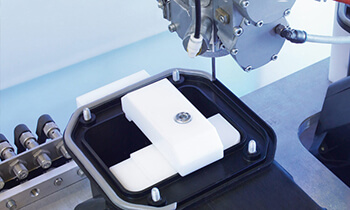

Formed-in-place foam gaskets

For the most demanding technical injection moulded parts with additional seals.

Hot-gas welding

For particle-free seams suited for media-carrying (air, oil or water) components.

MuCell® method

For molded parts with reduced weight and increased mold stability.

Cleanroom production

For specific cleanliness requirements (GMP Class C).

Interesting downloads:

This could also interest you:

CONTACT

Do you have any questions? KAPSTO® team will be happy to answer them.

On-site

Our sales representatives can come straight to your premises. Make an appointment now.

+86 (0) 512 3662 9486

By e-mail

Twenty-four hours a day. We will get back to you as soon as possible.

You might also be interested in the following topics: