CONCEPT TECHNICAL CLEANLINESS

From normal production to cleanroom production.

Due to their complex, technical requirements, many systems are very sensitive with regard to pollution. Especially in the automotive industry, systems such as the engine compartment, brakes, gearbox or fuel are vulnerable: even the smallest particles can lead to failure. Compliance with ever stricter cleanliness requirements is therefore a growing issue, even in the production of technical plastic parts. The aim is to keep the contamination of sensitive technical components as low as possible.

In order to implement the different components according to individual requirements in a most cost-effective and economical manner, we carry out the Quick Check. Pöppelmann K-TECH® not only analyses technical cleanliness on accordance with VDA volume 19 but also lives it right from the beginning and it even has become an integral part of our project management.

Depending on the specific requirements, we can decide which components require special production in terms of their technical cleanliness. To be able to meet the increased demands of our customers, we can produce the components in a clean room with special air filtration systems. For even more cleanliness, we also have the possibility to produce in a cleanroom. The special filtration systems guarantee particle and germ contents in accordance with DIN EN ISO 14644 – class 7 and class C of the EC GMP guideline. This means: less than 350,000 particles/m³ down to a size of 0.6 µm, and less than 100 nucleating agents/m³. Highest cleanliness for sensitive systems!

„When foreign particles are absolutely taboo.“

Learn how Michael Dultmeyer and his colleagues not only ensure technical cleanliness for high-precision plastic parts but even live it. > Watch now

Different methods, one goal: uncompromising cleanliness.

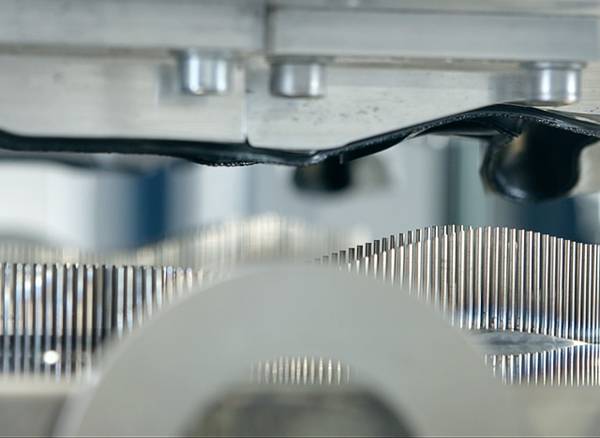

In order to meet our claim and get the best out of each project, we implement technical cleanliness requirements using different methods. In the production we rely on encapsulated machines. During the process, all necessary steps must be defined in relation to the requirements – this applies to both the tool and the periphery of the machine. Last and not least, technical cleanliness is checked and ensured in our own lab during series production.

During production, we offer the possibility of producing plastic parts under standardised conditions, depending on requirements and the number of pieces. This gives us better control on external factors such as human, production environment and machine.

You can find more information about the Pöppelmann K-TECH® FIPFG gaskets in our Competences section. > Find out more

During series production, Pöppelmann carries out measurements to check for technical cleanliness in its own lab. To do this, reference parts are taken from production, washed and the proportionate particles are caught in a special sieve to be then evaluated and documented according to their categorisation.

PÖPPELMANN KAPSTO®

In case you are looking for a purely standard solution.

Pöppelmann KAPSTO® offers plastic protective elements for all applications. The extensive standard range includes about 3,000 versions – available for immediate delivery.