FASTLANE

In the fast lane to the special part.

Individual protection elements with a super-fast turnaround time – our new optional service makes it possible: With FastLane we can now develop and produce your special part even faster. In this way, we provide you with the best possible support in the event of time bottlenecks, and you benefit from extremely short response times and maximum manufacturing flexibility.

Through the tight time frame with a streamlined process.

As soon as you make an inquiry with this new service, you receive the quote within 24 hours and an item concept in the form of a technical drawing or sketch.

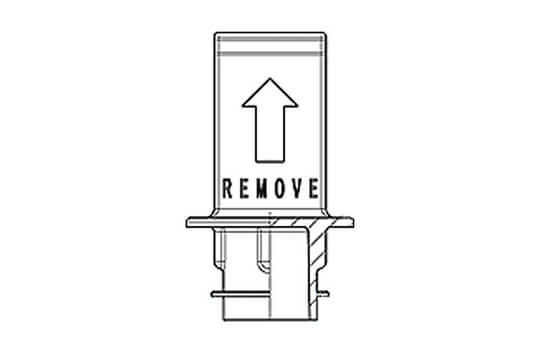

After completing the CAD-based item design we produce your initial prototypes on this basis within one week. In order to allow you to check the basic functionality and characteristics on this functional prototype immediately, we use the Rapid Prototyping or Rapid Tooling 3D printing procedure to manufacture the part (depending on requirements).

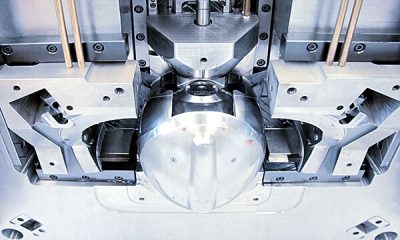

Just one month after successful agreement, you then receive the first off-mould parts from the series production of your customised item.

The advantages of FastLane at a glance:

We do it. Faster.

The success factors of Pöppelmann KAPSTO® are not least our employees. With FastLane, this can look as follows:

As your personal contact, Sebastian agrees the requirements for the new special part with you. In order to produce the quote, Rüdiger develops the first item design in one day, which is constructed on a CAD basis by Elisabeth after customer approval. Then, Michael – our specialist for 3D-printed functional prototypes – manufactures the first prototype.

As soon as the agreed protection element is ready to go into series production, Engin becomes involved: in our in-house mould construction area he can manufacture the tools that are required extremely quickly. Günter then takes care of the installation of the new tool and starts to produce your individual special parts.