FURNISHING PARK

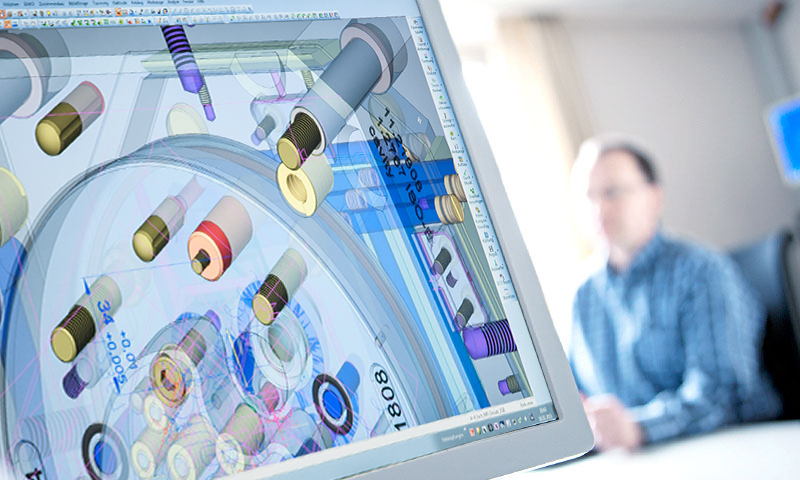

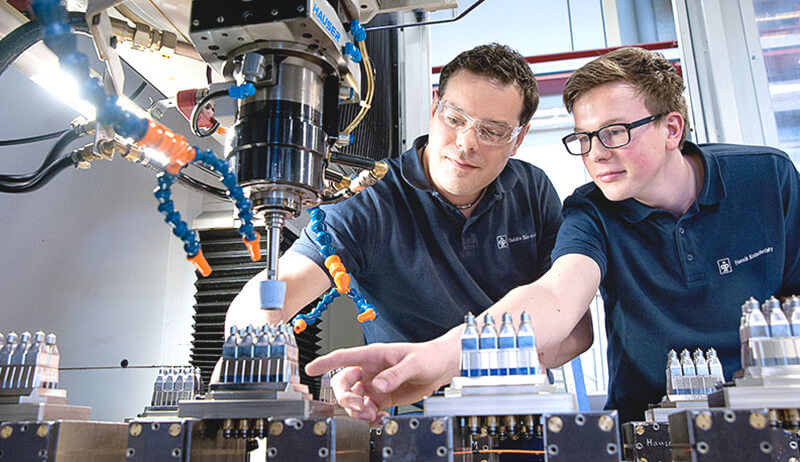

State-of-the-art technology: our machinery.

By using the latest technology, we are able to produce moulds with even greater precision, even faster and – in many cases – more cost-effectively. For this reason, we are constantly updating our comprehensive furnishing park. Some details of the performance of the individual machines can be found below. We are happy to answer any further questions you may have.

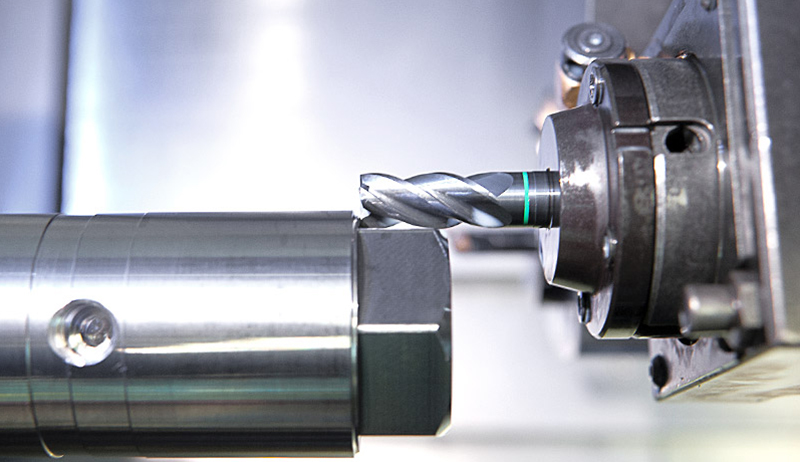

5-axis CNC milling

CNC-controlled 5-axis milling processes allow complex geometries with dimensions of up to 600 x 600 x 500 mm to be produced.

HSC milling

We machine graphite electrodes and hardened components on our HSC milling unit. The traverse distances are approximately 650 x 550 x 400 mm.

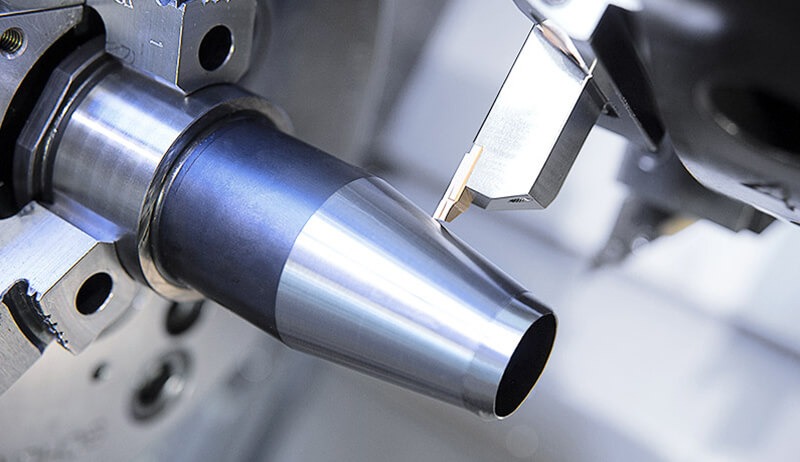

CNC turning

Our daily tasks also include CNC-controlled turning. This process allows us to machine components with a diameter of up to 420 mm and an installation height of up to 1,200 mm.

Hard finish turning

One of the most modern technologies used by Pöppelmann WTZ is finish turning of hardened components – with diameters of up to 380 mm. This often eliminates the need for additional production steps such as grinding.

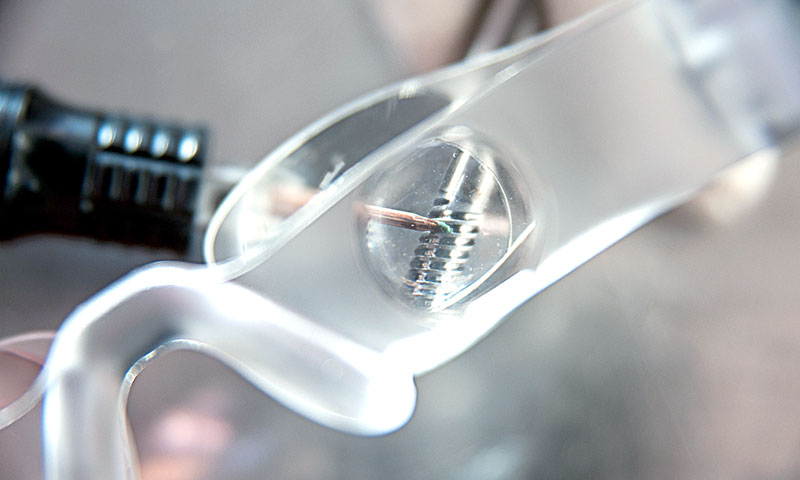

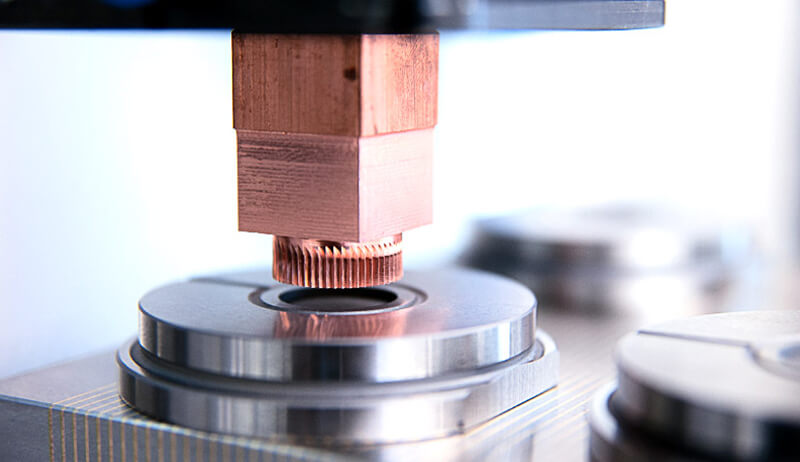

Electric discharge machining (EDM)

In addition to the metal-removing processes, we can manufacture the contoured moulded parts on our EDM machine, which offers maximum traverse distances of 700 x 500 x 500 mm.

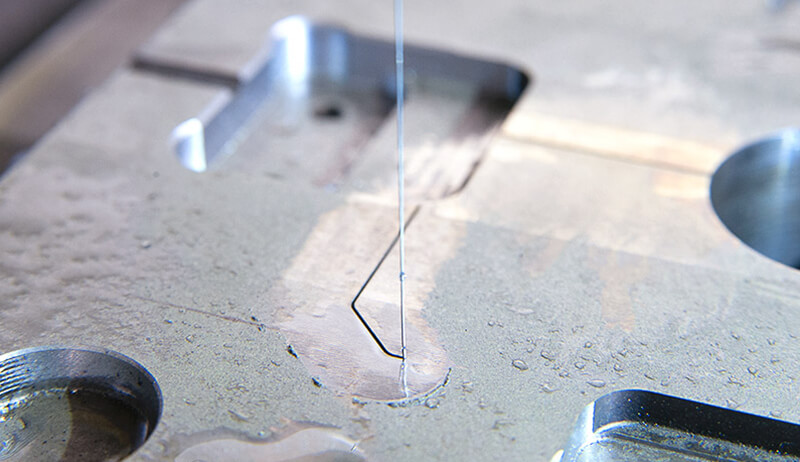

Wire EDM

High-precision contouring is achieved in a variety of ways that includes wire EDM. The traverse paths are approximately 500 x 350 x 300 mm.

Surface and profile grinding

In our grinding shop, level surfaces and profiles across an area of 1500 x 750 mm (with a maximum component height of 500 mm) can be machined.

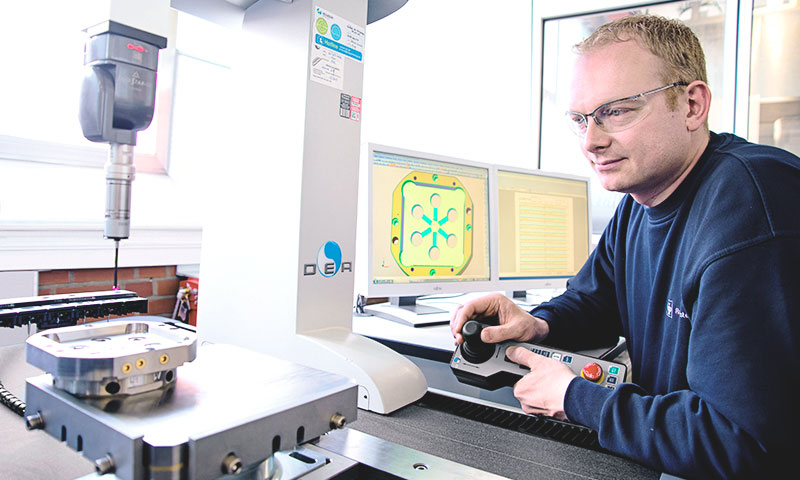

Jig grinding

High surface qualities are achieved using various technologies that include our jig grinding machines. Here, we can machine components with dimensions of up to 1200 x 800 mm.