DEVELOPMENT PARTNER

Developing plastic solutions.

Customer-oriented and competent: With Pöppelmann as your development partner, you have quality and costs under control right from the beginning. We offer you all the plastic expertise that is required for your project, under one roof. From design, through rapid development tools (e.g. Rapid Prototyping) and in-house mould making, to efficient high-end serial production. A project manager takes good care of your interests, at all times. – For the ultimate competitive advantage.

Our development capabilities are in line with the latest products, technologies and the highest market demands. Quality, perfect craftsmanship and high-tech production are the secrets behind our market-leading success.

The advantages from development to serial production at a glance:

From development to serial production.

1.) Competent, customer-oriented project management.

Our stress-free package for you: we undertake all those numerous little jobs which a project involves. As our customer, you will therefore save a lot of time and the costly doubling up of work, for example, with external development agents and mould constructors.

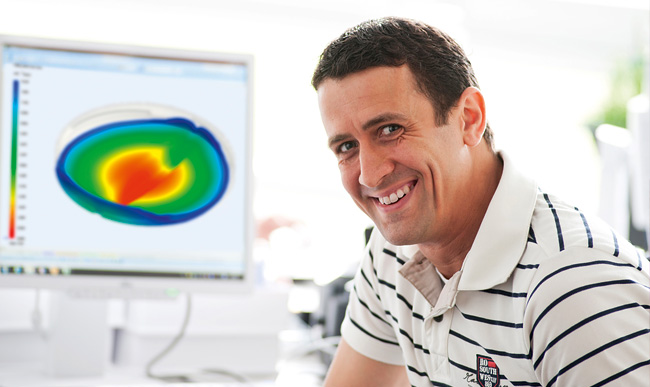

2.) Modern and fast CAD-controlled development tools.

Virtual product development and optimisation as an efficient key to standard mould design and manufacture.

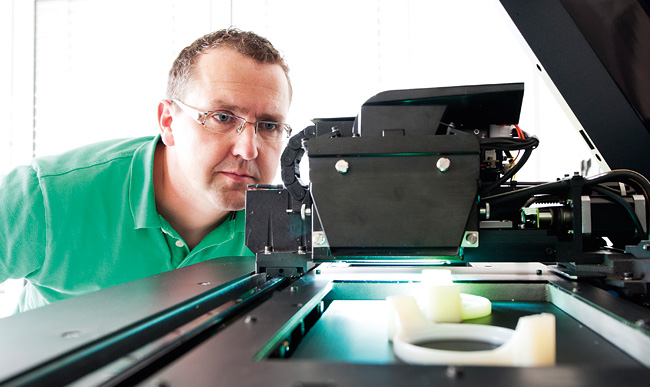

3.) Rapid Prototyping.

Rapid prototyping (SLS/SLA/3D printing) makes design and functional prototypes available right from the early development stages.

4.) Highest precision in our own tool shop.

Precision enables the manufacture of sophisticated plastic parts and ensures trouble-free high-performance production. Our own toolmaking facility guarantees fast response and extreme flexibility when it comes to mould construction, modification and repair.

5.) Efficient serial production.

Consistent quality, high production output and exemplary cleanliness distinguish our GMP-class-E production facility. Modern machinery with closing forces of between 250 kN and 13,000 kN is a sign of reliable series production.

DEVELOPMENT TOOLS

Better solutions in a shorter time.

The development of new plastic solutions is one of the particular strengths of Pöppelmann K-TECH®. As our customer, you define the requirements – we develop the right solution.

RAPID PROTOTYPING

The faster route to series maturity.

From idea to model. Rapid Prototyping allows Pöppelmann to create individual testing samples in different materials, even in early development stages.

IN-HOUSE LEAKAGE TESTS

Safe and budget-conscious.

Pöppelmann uses a protection-class test chamber for in-house leakage tests during development stages.

This could also interest you:

Discover more technology films on our Youku channel, PöppelmannTV.