MEASUREMENT TECHNOLOGY

Go ahead and take a closer look: our quality assurance.

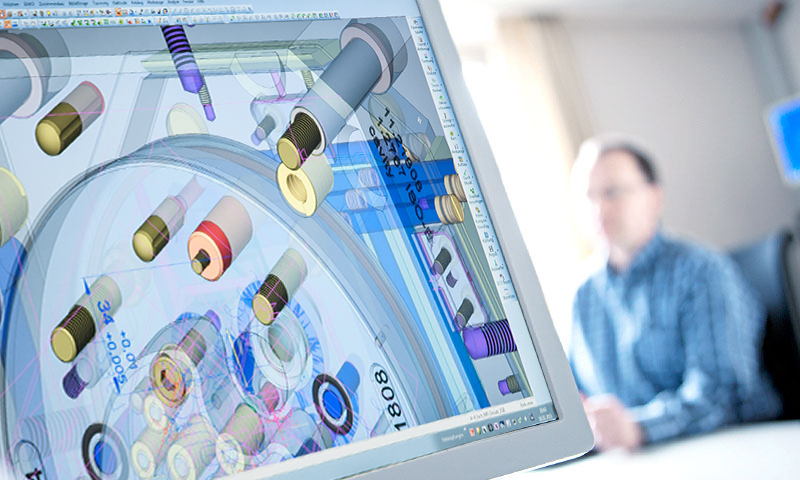

In the area of measurement technology, we verify our high-precision products every day. All specified reference dimensions on the moulded parts are carefully measured, checked, and documented. We can avail of all the main measurement procedures for this purpose. Particularly sensitive measurements are taken in a separate, climate-controlled measuring room.

With regard to materials, we can also carry out the necessary quality inspections of our components in our MOULD-MAKING department. In this case, we test a range of parameters including the reliable hardness values of the Rockwell scale. We also use a mobile spectrometer to carry out material analyses for steels, copper and aluminium alloys as part of the incoming goods inspection.

Control is better: a Pöppelmann employee at the measuring microscope performs a two-dimensional measurement.

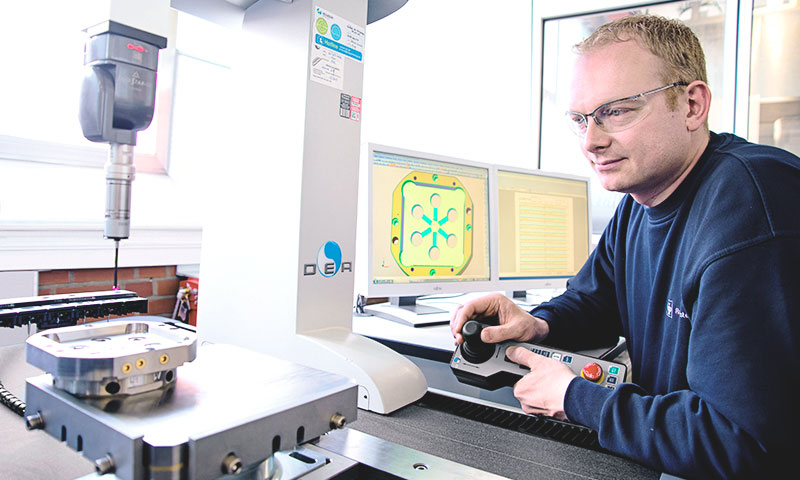

Focussed on top-class performance: our coordinate measuring machine takes three-dimensional measurements.

The ultra-modern wave measuring machine is used to check the component geometry.

In focus: surface quality.

We can check the surface quality of our workpieces with a contour and surface measurement device that scrutinizes the roughness and profile parameters while at the same time monitoring tolerances.