PRECISION

Precision guarantees perfection.

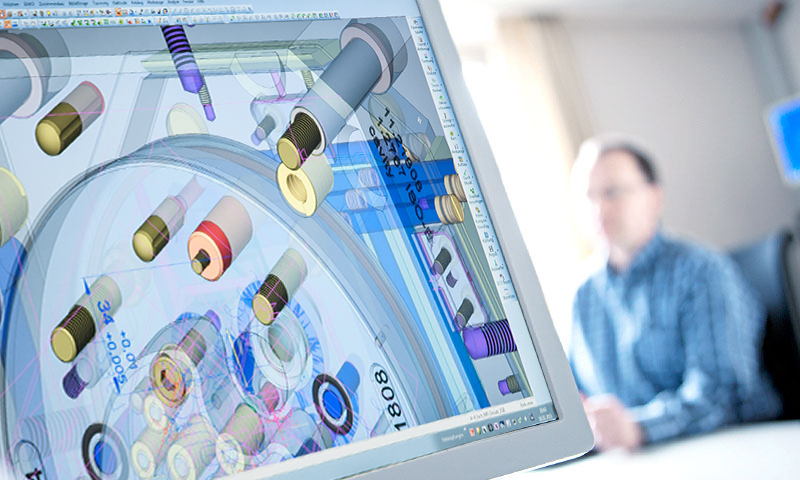

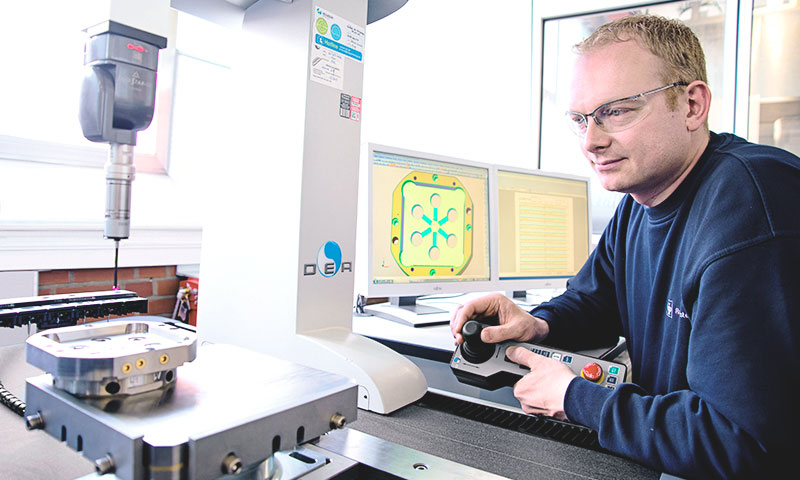

For quality assurance purposes, we operate a dedicated project support system in our precision area for components with minimal tolerances – backed by dedicated work scheduling and an interface to the construction department.

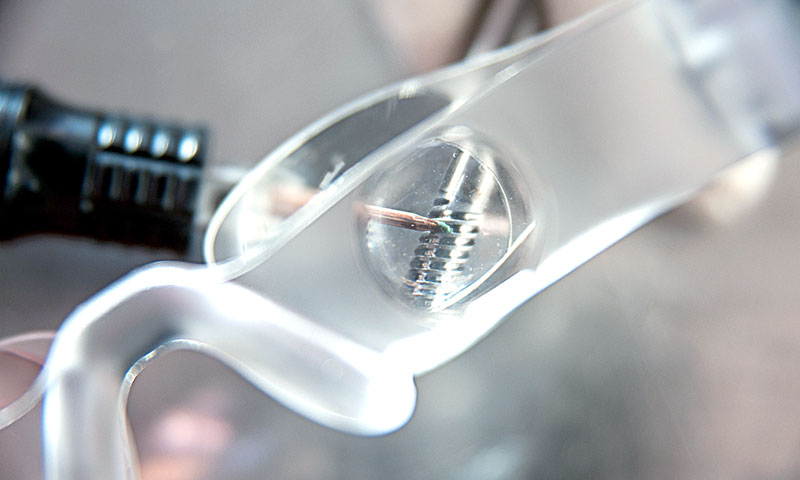

For us – and naturally for our customers – one of the key success factors is precision. That is because it ultimately determines the contour accuracy of our moulds. To achieve tolerances of just 5 µm on formative parts, we machine the components in a dedicated climate-controlled area. After the hardening process, the workpieces receive their final contour. This procedure allows us to ensure reproducibility of individual components and guarantees quality assurance.

Our high-precision production processes range from surface, cylindrical, and profile grinding through to jig grinding all the way to EDM. The use of other ultra-modern production processes such as hard finish turning and hard finish milling often eliminates the need for production steps such as grinding. At the same time, high surface qualities and surface tolerances are fulfilled.